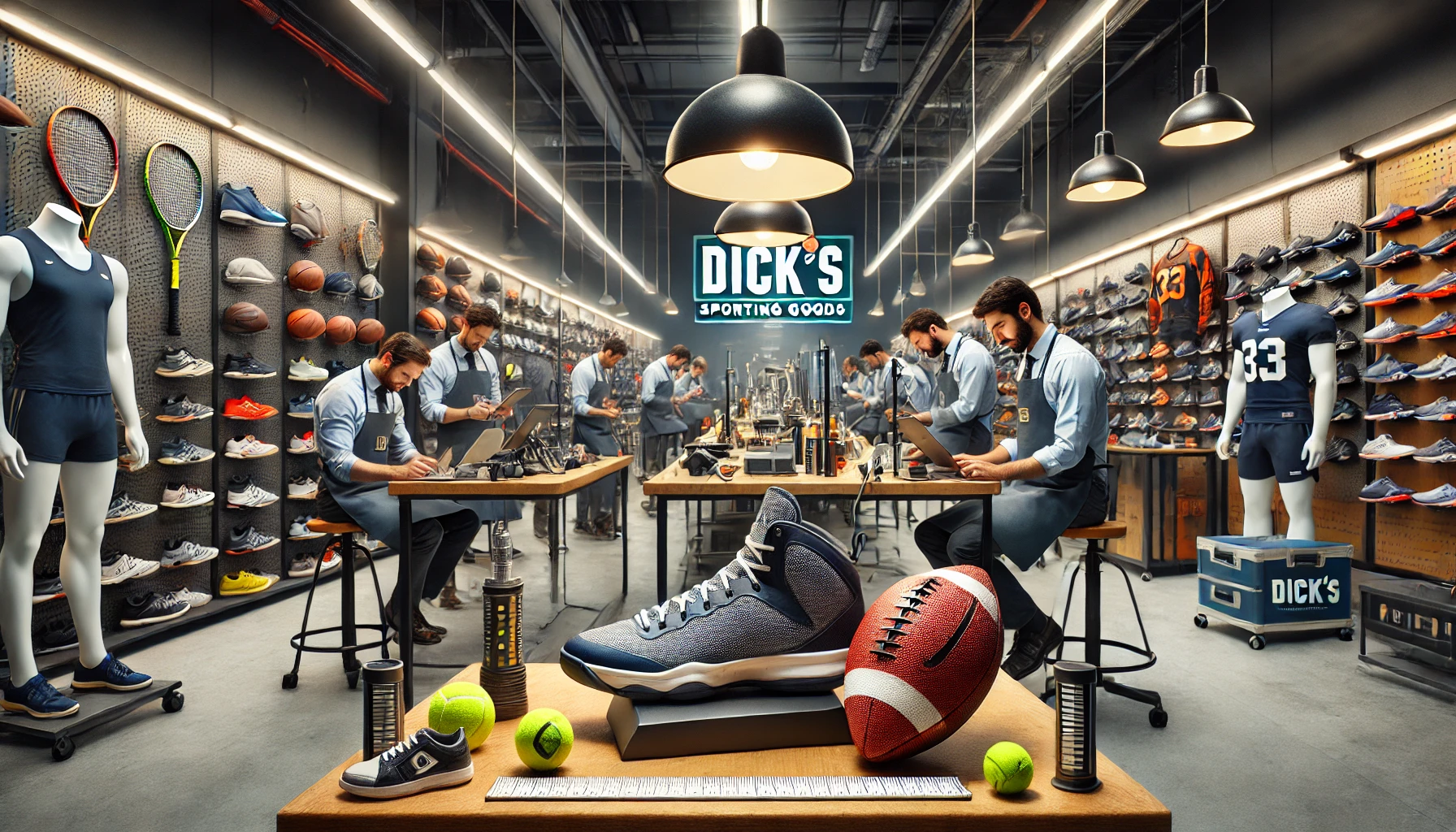

How to Test Products for Dick’s Sporting Goods: A Complete Guide for Retailers and Manufacturers

Introduction to Testing Products for Dick’s Sporting Goods

When it comes to retailing sports and outdoor equipment, Dick’s Sporting Goods stands as one of the largest and most trusted names in the industry. With thousands of stores across the United States and a significant online presence, Dick’s Sporting Goods has set high standards for product quality, durability, and performance. This means that every product sold at their stores, from sports gear to outdoor equipment, needs to meet specific criteria before it can be stocked on their shelves.

For manufacturers and vendors looking to get their products into Dick’s Sporting Goods, understanding how to test products is crucial. Testing not only ensures that products meet industry standards but also guarantees customer satisfaction and reduces the risk of returns due to poor quality. In this article, we’ll explore everything you need to know about testing products for Dick’s Sporting Goods, including the testing procedures, key criteria, and best practices.

Why Product Testing is Crucial for Dick’s Sporting Goods

Product testing is at the core of every successful retail strategy, especially for a store like Dick’s Sporting Goods. Retailers depend on product testing to ensure that the products they sell are safe, functional, and aligned with customer expectations. For a company like Dick’s, the stakes are higher since it serves athletes, outdoor enthusiasts, and sports lovers who demand the highest quality.

Key Reasons Why Product Testing is Essential

- Ensures Safety: Safety is the top priority when it comes to sports equipment and outdoor gear. Testing helps identify potential hazards, such as faulty materials or poor construction, that could lead to accidents or injuries.

- Maintains Quality Standards: Product testing ensures that every item that reaches the shelves of Dick’s Sporting Goods meets the company’s rigorous quality standards. This includes everything from the durability of sportswear to the reliability of outdoor gear like tents and sleeping bags.

- Improves Customer Satisfaction: Testing is integral to providing customers with the best possible experience. When products meet or exceed expectations, it leads to higher customer satisfaction and builds long-term brand loyalty.

- Prevents Returns and Complaints: High-quality testing reduces the likelihood of returns due to defective or subpar products. This ultimately saves Dick’s Sporting Goods money and protects the brand’s reputation.

Types of Products Tested by Dick’s Sporting Goods

Dick’s Sporting Goods stocks a wide variety of products, each requiring specific testing methods. These products range from clothing and footwear to sports equipment and outdoor gear. Understanding which types of products undergo rigorous testing will help manufacturers tailor their approach to meet the necessary standards.

Categories of Products Tested

- Athletic Apparel: Clothing designed for sports, fitness, and outdoor activities undergo extensive fabric and durability testing. This includes checking for moisture-wicking properties, elasticity, and resistance to wear and tear.

- Footwear: Running shoes, hiking boots, cleats, and other types of footwear must pass rigorous performance and comfort tests. Key factors like cushioning, arch support, waterproofing, and durability are tested to ensure that they meet consumer expectations.

- Sports Equipment: This includes everything from basketballs and soccer balls to tennis rackets and golf clubs. Testing often focuses on performance, such as how well a basketball bounces, how well a tennis racket absorbs shock, or the balance of a golf club.

- Camping and Outdoor Gear: Tents, sleeping bags, and backpacks are all tested for factors like weight, comfort, ease of use, and weather resistance. For camping gear, durability in harsh outdoor conditions is a critical factor.

- Fitness Equipment: Home gym equipment like treadmills, weights, and yoga mats are tested for ease of use, stability, safety, and effectiveness in various workout routines.

- Cycling Equipment: Bikes, helmets, and accessories undergo specific tests for safety and performance, including tests on stability, comfort, and overall usability.

The Product Testing Process for Dick’s Sporting Goods

Testing products for Dick’s Sporting Goods involves multiple stages and requires close attention to detail to meet the retailer’s high standards. Let’s walk through the typical product testing process, highlighting key steps involved from initial product submission to approval.

Step 1: Submitting Product Samples for Evaluation

Manufacturers and suppliers must first submit samples of their products for evaluation by Dick’s Sporting Goods. These samples are sent to the company’s internal product testing department or third-party testing facilities, where they will undergo a series of rigorous assessments.

Step 2: Preliminary Evaluation and Screening

Once the product samples are received, the testing team conducts a preliminary evaluation. This often includes basic visual inspection to ensure that the product meets the company’s standards in terms of appearance, material quality, and functionality. Any products that fail the preliminary evaluation are sent back for redesign or improvement.

Step 3: Performance Testing

For products that pass the initial screening, performance testing takes place. This is the most crucial phase of testing, where products are subjected to rigorous conditions to assess their effectiveness and reliability. Here are some common performance tests:

- Durability Testing: This involves subjecting products to wear and tear to see how they hold up over time. For example, sports shoes may be tested for tread wear, while outdoor gear is subjected to harsh weather conditions to test its durability.

- Load Testing: Sports equipment, like gym benches or fishing rods, may be subjected to load-bearing tests to evaluate their strength and performance under stress.

- Functionality Tests: Sports equipment and outdoor gear often undergo tests to ensure that all functions work as intended. For instance, a tent is tested for ease of setup, waterproofing, and ventilation.

Step 4: Safety and Compliance Testing

Safety is a top priority for Dick’s Sporting Goods, and every product must meet specific safety standards before it can be sold. Depending on the product category, various safety tests are conducted:

- Toxicity Testing: For certain products like children’s gear or fitness equipment, toxicity testing ensures that no harmful substances are present in the materials.

- Structural Integrity: Sports equipment like bicycles or skis undergo tests to check for structural integrity to prevent breakage or failure during use.

Step 5: Final Approval and Packaging

Once the product passes all tests, it undergoes a final inspection before receiving approval to be stocked by Dick’s Sporting Goods. Packaging is also reviewed to ensure it complies with the company’s branding and regulatory standards.

Key Criteria for Testing Products at Dick’s Sporting Goods

Understanding the core criteria used in the testing process can help manufacturers design and produce products that are more likely to pass the testing stages. These criteria are aligned with Dick’s Sporting Goods’ mission to provide high-quality, durable, and safe products to its customers.

Performance and Functionality

Products must perform as expected under real-world conditions. Whether it’s a pair of running shoes or a camping tent, the product should meet the customer’s functional needs. For example, footwear should offer comfort, support, and traction, while camping gear should be weatherproof and easy to set up.

Durability and Longevity

Dick’s Sporting Goods places a strong emphasis on durability. Products are expected to last, even after prolonged use. Whether it’s athletic gear that gets frequent use or outdoor equipment exposed to the elements, testing for durability ensures that customers get long-lasting value.

Safety Standards

Safety is a non-negotiable aspect of product testing. All products must meet safety standards, especially for children’s products and outdoor gear that may be subjected to extreme conditions. Whether it’s a helmet or a fishing rod, testing ensures that there are no inherent risks to customers.

Compliance with Regulations

Products must also comply with local, state, and federal regulations. For example, children’s products must meet the Consumer Product Safety Improvement Act (CPSIA) guidelines, while sporting goods should follow ASTM (American Society for Testing and Materials) standards.

Best Practices for Manufacturers When Testing Products for Dick’s Sporting Goods

Manufacturers looking to get their products on the shelves at Dick’s Sporting Goods should be mindful of several best practices that can increase the likelihood of passing the testing process. Here are some tips for success:

1. Understand the Testing Requirements

Before submitting products for testing, manufacturers should familiarize themselves with Dick’s Sporting Goods’ specific testing requirements. Understanding the company’s quality, safety, and performance standards is crucial to ensuring a smooth testing process.

2. Provide Detailed Product Information

Providing detailed specifications and descriptions of the product helps the testing team understand its intended use and key features. Include all relevant information about materials, construction, and any unique design elements.

3. Test In-House Before Submitting

Manufacturers should conduct their own internal testing before submitting products for formal evaluation. This allows them to identify and address potential issues before the product goes through Dick’s official testing process.

4. Invest in Quality Control

Maintaining high-quality standards throughout the manufacturing process can significantly improve the chances of a product passing testing. Quality control measures, such as checking for defects in production or using high-quality materials, are essential for success.

Conclusion

Testing products for Dick’s Sporting Goods is a vital process that ensures only the best products make it to the shelves. From safety testing to performance evaluation, every product must meet stringent standards to satisfy the retailer’s quality requirements. By understanding the testing process, manufacturers can better prepare their products for success and contribute to the high-quality offerings that Dick’s Sporting Goods is known for.

In summary, rigorous product testing benefits both manufacturers and consumers by ensuring safety, performance, and long-lasting durability. Manufacturers who follow best practices, such as understanding the testing requirements and investing in quality control, can improve their chances of success in getting their products into one of the largest and most respected sporting goods retailers in the United States.

Post Comment